Welcome to the world of Programmable Logic Controllers (PLC)! Today marks the beginning of your journey into understanding the essential components and functions of PLC systems. By the end of this blog, you will have a solid understanding of what a PLC is, its importance in industrial automation, and the basic components that make up a PLC system. Let's get started!

What is a PLC?

A Programmable Logic Controller (PLC) is a digital computer used for automation of industrial processes, such as control of machinery on factory assembly lines, amusement rides, or lighting fixtures. PLCs are designed for multiple inputs and output arrangements, extended temperature ranges, immunity to electrical noise, and resistance to vibration and impact.

Definition and Importance of PLCs:

PLCs are essential for industrial automation because they offer:

- Reliability: Robust hardware designed to withstand harsh industrial environments.

- Flexibility: Programmable to control a wide range of applications.

- Scalability: Modular design allows for easy expansion and customization.

- Ease of Maintenance: Simple troubleshooting and diagnostic capabilities.

Industries that Use PLCs:

- Manufacturing

- Automotive

- Food and Beverage

- Pharmaceuticals

- Water Treatment

- Oil and Gas

Components of a PLC System:

A typical PLC system consists of the following components:

- Power Supply: Provides the necessary power to the PLC system.

- Central Processing Unit (CPU): The brain of the PLC, responsible for executing control instructions stored in the memory.

- Input/Output (I/O) Modules: Interfaces that allow the PLC to receive input signals from sensors and send output signals to actuators.

- Communication Modules: Enable communication between the PLC and other devices, such as HMIs (Human-Machine Interfaces) and other PLCs.

- Programming Device: Used to write and upload the control program to the PLC. This can be a computer with PLC programming software.

Basic PLC Operation:

- Input Scan: The PLC reads the status of input devices (e.g., sensors) and stores the data in memory.

- Program Execution: The CPU executes the control program based on the input data.

- Output Scan: The PLC updates the status of output devices (e.g., actuators) based on the results of the program execution.

Hands-On Practice:

To get hands-on experience, you can use a PLC simulation software like TIA Portal, RSLogix, or a physical PLC development kit.

- Set Up the Development Environment:

Download and install the PLC programming software suitable for your PLC hardware or use a simulation environment.

- Create a Basic PLC Configuration:

- Configure the PLC hardware setup in the software.

- Define the input and output modules.

- Write a Simple Control Program:

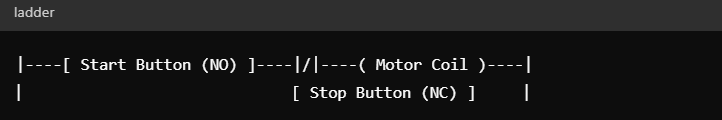

- Use Ladder Logic (a graphical programming language) to create a simple program that turns on a motor when a button is pressed.

Example of a Simple Ladder Logic Program:

Key Takeaways:

- PLCs are essential for industrial automation, providing reliable, flexible, and scalable control solutions.

- Understanding the basic components of a PLC system is crucial for designing and implementing automation projects.

- Hands-on practice with PLC simulation software or development kits helps reinforce your understanding of PLC operation and programming.

Congratulations on completing Day 1 of your PLC journey! You've learned the basics of what a PLC is, its importance in industrial automation, and the components that make up a PLC system. Tomorrow, we will dive deeper into PLC programming languages and explore basic control logic. Happy learning!